To understand technical systems and machines - I can always get fascinated by that. Due to that I decided to start studying mechanical engineering at Environmental-Campus Birkenfeld. At this place I had the possibility to combine theoretical knowledge with aspecs of sustainability. Especially the so called additive manufacturing has great potentials for material saving with an innovative form design in combination with the optimization of processes. In specific this combination transferred to the bioprocess technology and especially to biorectors already facinated me in my master´s thesis. Through my participation the doctorals program ParaMorphoPharm, I can continue to work on this interface of mechanical engineering and bioprocess engineering and thus identity optimization potenzials in cultivation of fungi. The aim is to make cultivation processes more efficient and thereby more sustainable through design and additive manufacturing.

Aim is the optimization and additve manufacturing of novel reactor internals for fungi fermentation with a special focus on the stirrer geometry. Using the reactor internals to be developed, a growing environment could be provided, which is characterized by low shear stresses with consistent fungi quality. Through optimization of the process (with a view to upscaling to industrial scales) with the help of computational simulation tools, failed culitvations could be avoided and costs and thus further ressources can be saved.

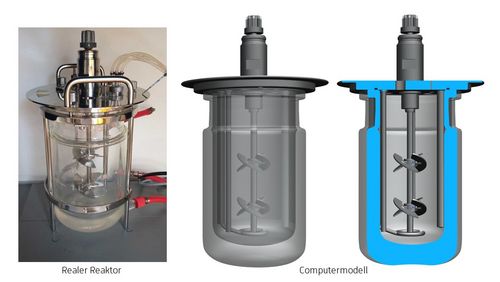

Filamentous fungi are cultivated in bioprocess engineering in bioreactors, especially in stirring reactors, to obtain pharmaceutically interesting substances. In addition to the cultivation conditions provided by the configuration of the cultivation liquid, the reactor components such as stirrers and sensors also have an influence on the cultivation process. My exercise is to investigate the influence of different geometries and set-ups of reactor internals inside the culitvation vessel. Especially the observation of shear stresses as a consequence of stirring has a special relevance, as shear stress has a major impact on the morphology of fungi.

In a first step I digitalized the conventional used bioreactor and exported him into a software for fluid simulation. This software allows the evaluation of shear stresses and mixing times of substances in fluid. I use this mixing time evaluations for the comparison with real mixing time experiments and as a consequence for the validation of software. The simulation of the actual state allows me to identify potentials for optimization inside the reactor. In specific, the aim is to investigate the effects of particular geometric changes and to apply these in an iterative optimization process for an improved reactor configuration. After designing new components , these can then be additively manufactured from plastic or metal, depending on the application. In addition to the iterative optimization work, material studies are also carried out to examine the various 3D-printing processes and available material options in terms of their suitability for use in bioprocess-engineering. These include testings for material strength or tightness.

Summarized, the aim of my work is the optimization of the reactor internals using simulation based design, additive manufacturing and validation of the optimization by testing the internals in use. As a perspective, recommendations for industrial use can then be determined from the internals developed.

A typical work day begins with the configuration of a new simulation. While calculating the simulation I do some literature work or I design new simulation setups. In addition I operate several 3D-printers, which is a good variation from working on the computer.

Hoffmann, L.J.; Brinkmann, J.; Huwer, A.; Wahl, M.; te Heesen, H.: Praxisorientierte Konstruktion in der additiven Fertigung: Anwendung der Konstruktionsmethodik am Beispiel eines E-Scooters; Zeitschrift für den wirtschaftlichen Fabrikbetrieb (ZWF) 117(1-2): S. 30-34: DOI 10.1515/zwf-2022-1013

Brinkmann, J.; Bremer, M.; Huwer, A.; Hoffmann, L.J.; Wahl, M.; te Heesen, H.: Nachhaltigkeit durch Digitalisierung, additive Fertigung und innovative Prozesse in: Leal,W. (Hrsg.): Nachhaltigkeit in den Natur- und Sozialwissenschaften;DOI: 10.3726/b19330

You are leaving the official website of Trier University of Applied Sciences